Post by Andrew 2.8i on Feb 28, 2016 19:31:17 GMT

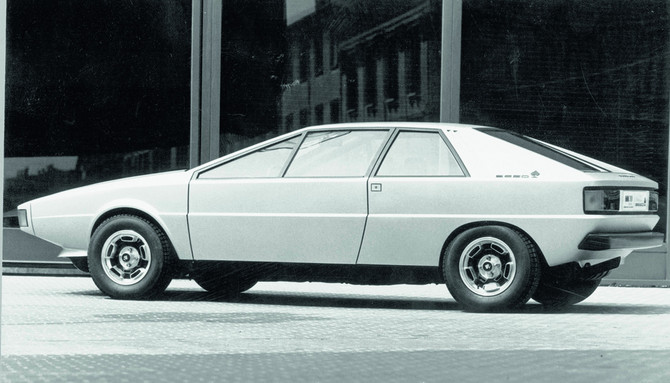

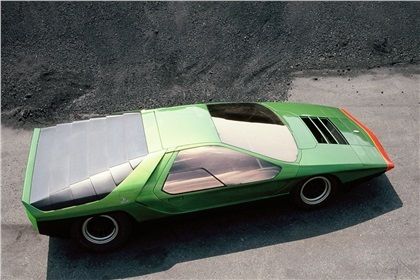

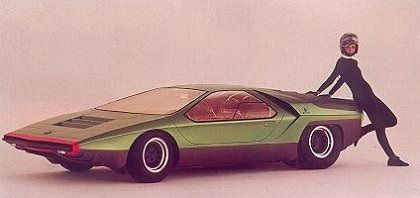

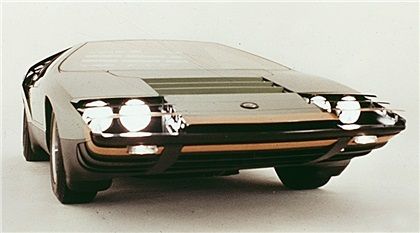

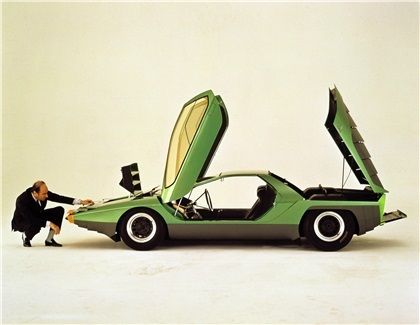

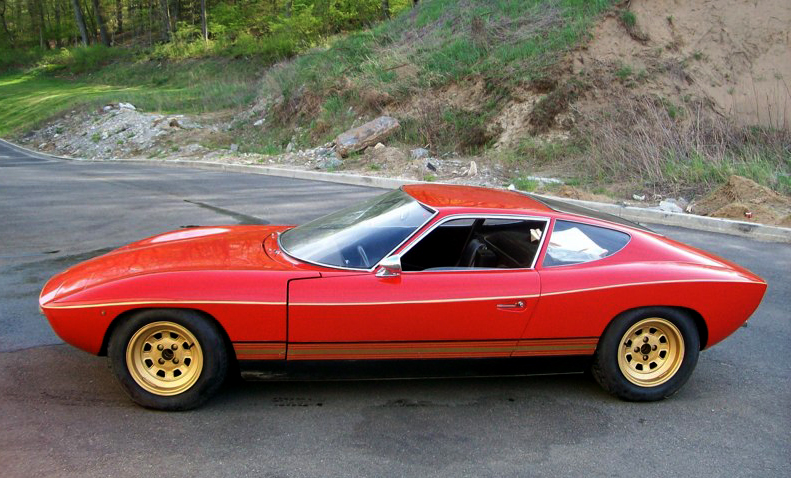

Leyland Force 7 Coupe.

.jpg)

The Force 7 came about as part of Leyland Australia’s plan to rebuild its reputation, using the promising P76 range of cars as the starting point. According to Adavanced Model Group (AMG) deputy leader, Barry Anderson, a coupe version was necessary in order to give Leyland an image boost in comparison to its bigger local rivals: ‘At the time, the family station wagon was a key element of our strategy of matching Holden, Ford and Chrysler because the wagon models accounted for some forty per cent of their sales volume… the coupe, or S2 as it was originally known, was only ever going to be a niche model for us. We saw it as an aspirational model for those who were seeking something different but also felt they had to buy a locally made car.’

Considering the tiny A$21 million budget Leyland had its disposal to cover the entire P76 programme, it is amazing to note that the coupe model shared no exterior panels with the P76 Saloon. It is also interesting to note that had the P76 Force 7V entered full-scale production, it would have been Australia’s first locally-designed hatchback.

Reg Fulford, the senior programme engineer for the P76 stated that, ‘…we were well aware of the risks, we went into the S2 part of the programme with our eyes wide open… there was little option but to use a different design over the same mechanical components.’

Obviously, the car had promise: John Mackesy, who worked on the project, related, ‘…I did quite a bit of driving of the S2, and have to say I remember it very fondly. It was a real driver’s vehicle and apart from being stylish was a very practical load carrier. I always thought it had possibilities for camping, too.’

Unfortunately, Leyland Australia collapsed before the P76 could reach fruition and the axe fell on the rest of the range. As it was, 58 cars were built in late 1973 for the planned launch in February 1974, before the plug was pulled. This run of now extinct models were ordered to the crusher – and in doing so they were driven from Zetland (The Leyland-Enfield plant in Sydney) to the Enfield Transport Terminal, where they were loaded onto trucks to take them to the Sims Metal scrap metal dealers.

Of these, 10 cars were auctioned off on the understanding that they were ‘Uncompliant’ for road useage (they had been complianced for use in Australia, but had their VIN plates removed), but most were subsequently registered anyway! One of these was shipped to the UK for evaluation, and was apparently used during the development of the SD1 (the Rover Sports Register reportedly accepts it as an SD1 prototype!). The car was later used by Lord Stokes as his personal transport, before being sold via auction to an enthusiast.

John Mackesy, who was at the auction, recalled, ‘I attended the auction where the 10 survivors were sold, and was also present when the prototypes and (pre?) production vehicles were destroyed. This was accomplished by dropping body dies on them from a large forklift, as I recall. They certainly weren’t driven anywhere outside the plant. As to the vehicle at Birdwood Mill (Adelaide) I drove this on a number of occasions, and in fact tuned and detailed it prior to its being sent away. I’m glad to see it still survives.’

According to Warrewyk Williams, all ten of these Force 7s survive to this day.

.jpg)

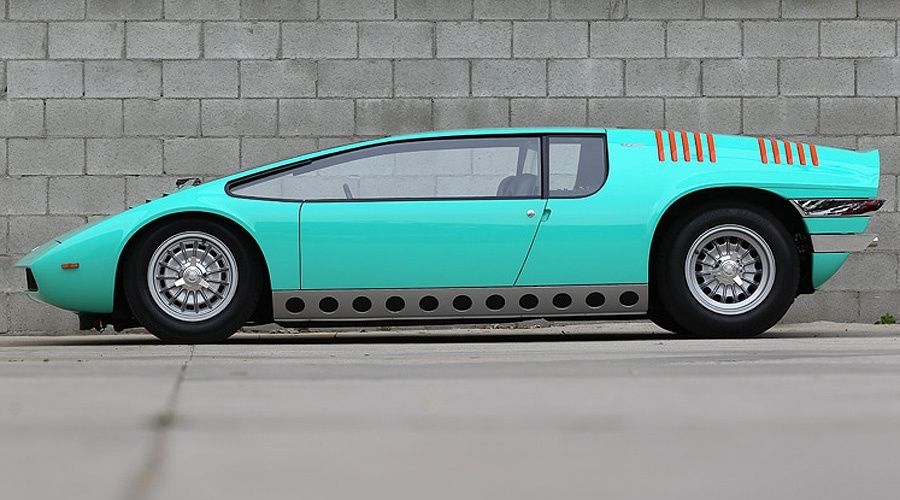

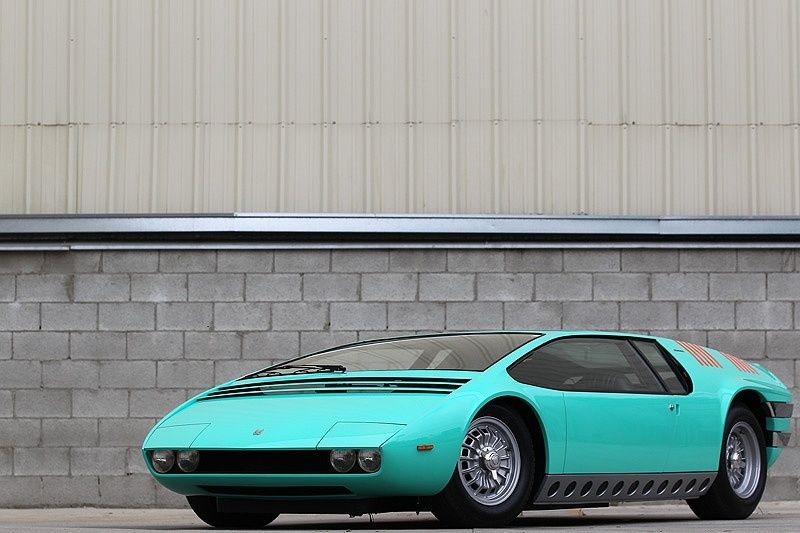

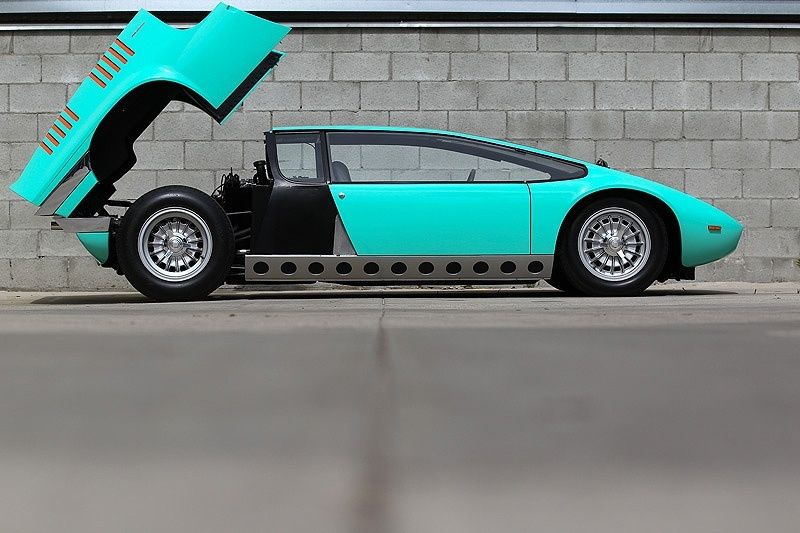

The Force 7 came about as part of Leyland Australia’s plan to rebuild its reputation, using the promising P76 range of cars as the starting point. According to Adavanced Model Group (AMG) deputy leader, Barry Anderson, a coupe version was necessary in order to give Leyland an image boost in comparison to its bigger local rivals: ‘At the time, the family station wagon was a key element of our strategy of matching Holden, Ford and Chrysler because the wagon models accounted for some forty per cent of their sales volume… the coupe, or S2 as it was originally known, was only ever going to be a niche model for us. We saw it as an aspirational model for those who were seeking something different but also felt they had to buy a locally made car.’

Considering the tiny A$21 million budget Leyland had its disposal to cover the entire P76 programme, it is amazing to note that the coupe model shared no exterior panels with the P76 Saloon. It is also interesting to note that had the P76 Force 7V entered full-scale production, it would have been Australia’s first locally-designed hatchback.

Reg Fulford, the senior programme engineer for the P76 stated that, ‘…we were well aware of the risks, we went into the S2 part of the programme with our eyes wide open… there was little option but to use a different design over the same mechanical components.’

Obviously, the car had promise: John Mackesy, who worked on the project, related, ‘…I did quite a bit of driving of the S2, and have to say I remember it very fondly. It was a real driver’s vehicle and apart from being stylish was a very practical load carrier. I always thought it had possibilities for camping, too.’

Unfortunately, Leyland Australia collapsed before the P76 could reach fruition and the axe fell on the rest of the range. As it was, 58 cars were built in late 1973 for the planned launch in February 1974, before the plug was pulled. This run of now extinct models were ordered to the crusher – and in doing so they were driven from Zetland (The Leyland-Enfield plant in Sydney) to the Enfield Transport Terminal, where they were loaded onto trucks to take them to the Sims Metal scrap metal dealers.

Of these, 10 cars were auctioned off on the understanding that they were ‘Uncompliant’ for road useage (they had been complianced for use in Australia, but had their VIN plates removed), but most were subsequently registered anyway! One of these was shipped to the UK for evaluation, and was apparently used during the development of the SD1 (the Rover Sports Register reportedly accepts it as an SD1 prototype!). The car was later used by Lord Stokes as his personal transport, before being sold via auction to an enthusiast.

John Mackesy, who was at the auction, recalled, ‘I attended the auction where the 10 survivors were sold, and was also present when the prototypes and (pre?) production vehicles were destroyed. This was accomplished by dropping body dies on them from a large forklift, as I recall. They certainly weren’t driven anywhere outside the plant. As to the vehicle at Birdwood Mill (Adelaide) I drove this on a number of occasions, and in fact tuned and detailed it prior to its being sent away. I’m glad to see it still survives.’

According to Warrewyk Williams, all ten of these Force 7s survive to this day.